Outdoor clothing has always demanded, and forever will, a delicate balance of durability, comfort, and weather protection. While high-tech synthetics seem to be the rage these days, reverse sateen is a fabric with a rich history that blends classic appeal with practical performance. Used in everything from jungle fatigues to workwear, it can be found in the Filson Field Series.

To understand reverse sateen, we must first delve into the history of its parent weave, sateen. The story begins in ancient China, where silk production and advanced weaving techniques were pioneered over 2,000 years ago. The satin weave, characterized by floating weft (horizontal) yarns creating a smooth, lustrous surface, emerged as a symbol of luxury reserved for royalty and the elite.

After each conflict ended, copious amounts of surplus uniforms were released to the public nationwide through the myriad of Army/Navy stores.

The Silk Road was crucial in disseminating this prized fabric westward, reaching Europe by the 12th century. Italy became an early center for satin production, and the fabric’s popularity soared during the Renaissance. The development of sateen marked a significant shift. While traditional satin was made from silk, sateen utilized other fibers, primarily cotton, making it more accessible and affordable.

A key innovation and turning point in its history occurred with the invention of mercerization in 1844 by John Mercer. This process treated cotton fibers, enhancing their strength, luster, and dye affinity, significantly improving the quality of cotton sateen. Mercerization laid the groundwork for the transformation of the textile industry during the Industrial Revolution when cotton fabrics became a popular choice for a wide range of fabrics from clothing and hosiery to home textiles and industrial applications.

Clothing made with reverse sateen places the shinier and softer side of the fabric on the inside for comfort and the heartier side outside, where its matte face repels damage more easily.

As its name implies, reverse sateen is the underside of traditional sateen fabric. By flipping the cloth over, manufacturers utilized the higher count of warp (vertical) yarns on the fabric face. Clothing made with reverse sateen places the shinier and softer side of the fabric on the inside for comfort and the heartier side outside, where its matte face repels damage more easily.

Textile producers leveraging reverse sateen gained a competitive edge by offering a product combining traditional sateen’s best qualities with a heavier, matte fabric. Its affordability relative to silk and satin gave manufacturers access to price-sensitive markets. At the same time, its durability and premium feel allowed producers to maintain higher margins compared to basic cotton fabrics.

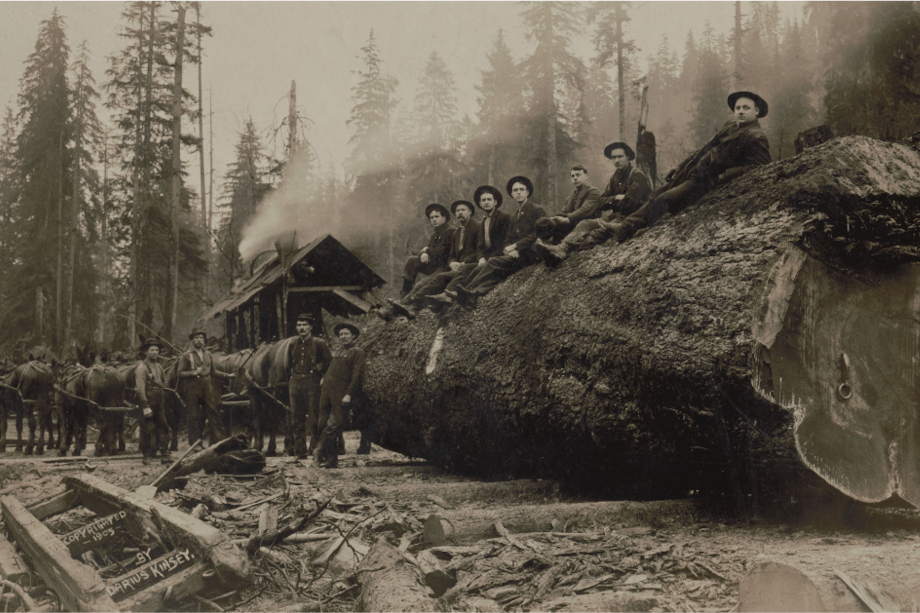

While it had been growing in use in the early 1900s, reverse sateen exploded into the public’s consciousness due to its widespread use in military fatigue uniforms, particularly in the United States during the mid-20th century. It was used in jungle fatigues and workwear uniforms in the Pacific Theater during World War II, the iconic M-51 field jacket during the Korean War, and in general uniforms until the late 1970s. The fabric offered a lightweight option that protected the troops while keeping them cool. After each conflict ended, copious amounts of surplus uniforms were released to the public nationwide through the myriad of Army/Navy stores.

The result was that laborers, hunters, campers, Boy Scouts, and others quickly adopted these durable, multi-functional military uniforms. Clothing producers took note, and a whole host of outdoor gear incorporated reverse sateen into their designs. Due to its tightly woven knit, reverse sateen is exceptionally resistant to abrasion and tearing, something crucial for garments that endure rough terrain. Plus, its dense weave created a natural barrier against wine. If cared for properly, reverse sateen clothing can develop a rich character as it ages.